GFRP (Fiberglass Reinforced Polymer) Rebar is a spiral wrapped structural reinforcing rod, it is one kind of composite material in market, Fiber reinforced composite is made of high performance fiber, synthetic resin (epoxy resin, vinyl resin, unsaturated polyester resin, etc.) matrix and curing agent. The fiber used are continuous fiber with high strength and high stiffness, FRP rebar can be used as an alternative to conventional steel reinforcement in structural concrete.

Product name: GRP/ FRP Rebar

Material: FRP/GRP

Color: Green or Customized Certificate:JG/T406-2013

Original: China

Loading Port: Tianjin,Qingdao,Shanghai.

Specification

FRP Rebar: Lightweight, Corrosion-Resistant Reinforcement Solution

FRP rebar (Fiberglass Reinforced Polymer rebar) is a high-strength, non-corrosive alternative to traditional steel reinforcement. Ideal for concrete structures in harsh environments, it offers exceptional durability in coastal, chemical, and infrastructure projects. With 1/4 the weight of steel and no thermal conductivity, it simplifies handling and enhances safety. Electromagnetic transparency makes it perfect for sensitive applications like hospitals and labs. Choose FRP rebar for longer-lasting, low-maintenance structures with superior resistance to rust and chemicals.

Boost your project’s lifespan and reduce lifecycle costs—contact us for quotes and technical support!

- Material: FRP/GRP

- Diameter: 3mm--40mm

- Color: Green or Customized

- Length: 6m, 12m or Customized

- Application: Civil construction

- Ultimate share strength:More than 150Mpa

- Modulus: 40Gpa

Technical Data

| No | Diameter (mm) | Ultimate tensile load(KN) | Cross section (mm2) | Ultimate tensile strength (MPa) | Modulus of elasticity (GPa) | Ultimate shear strength (MPa) | Weight (g/m) | ||||

| UP(1) | UP(2) | UP (1) | UP(2) | UP(1) | UP (2) | UP (1) | UP(2) | ||||

| 1 | 8 | 30 | 54 | 50.3 | 50 | 600 | 1080 | ≥40 | ≥110 | ≥150 | 105 |

| 2 | 10 | 47 | 67 | 78.5 | 73 | 923 | ≥40 | ≥110 | ≥150 | 165 | |

| 3 | 12 | 68 | 93 | 113 | 103 | 903 | ≥40 | ≥110 | ≥150 | 240 | |

| 4 | 14 | 80 | 118 | 133 | 134 | 880 | ≥40 | ≥110 | ≥150 | 280 | |

| 5 | 16 | 97 | 152 | 177 | 180 | 550 | 842 | ≥40 | ≥110 | ≥150 | 370 |

| 6 | 18 | 125 | 207 | 227 | 248 | 550 | 833 | ≥40 | ≥110 | ≥150 | 460 |

| 7 | 20 | 156 | 220 | 284 | 278 | 550 | 792 | ≥40 | ≥110 | ≥150 | 560 |

| 8 | 22 | 190 | 277 | 346 | 355 | 550 | 780 | ≥40 | ≥110 | ≥150 | 700 |

| 9 | 25 | 226 | 342 | 452 | 452 | 500 | 757 | ≥40 | ≥110 | ≥150 | 950 |

| 10 | 28 | 287 | 417 | 573 | 590 | 500 | 7071 | ≥40 | ≥110 | ≥150 | 1220 |

| 11 | 30 | 331 | 457 | 661 | 671 | 500 | 681 | ≥40 | ≥110 | ≥150 | 1350 |

| 12 | 32 | 378 | 497 | 755 | 740 | 500 | 672 | ≥40 | ≥110 | ≥150 | 1550 |

| 13 | 36 | 433 | 585 | 962 | 961 | 450 | 609 | ≥40 | ≥110 | ≥150 | 2040 |

| 14 | 40 | 538 | 640 | 1195 | 1190 | 450 | 538 | ≥40 | ≥110 | ≥150 | 2540 |

| No | Diameter (mm) | Ultimate tensile load(KN) | Cross section (mm2) | Ultimate tensile strength (MPa) | Modulus of elasticity (GPa) | Ultimate shear strength (MPa) | Weight (g/m) | ||||||

| EP | VEI | EP | VE | EP | VE | EP | VE | EP | VE | EP | VE | ||

| 1 | 6 | 28 | 28 | 28 | 28 | 1000 | 1000 | ≥50 | ≥40 | ≥150 | 60 | 60 | |

| 2 | 8 | 50 | 50 | 50.3 | 50 | 1000 | 1000 | 105 | 105 | ||||

| 3 | 10 | 79 | 69 | 78.5 | 73 | 1000 | 950 | 165 | 165 | ||||

| 4 | 12 | 113 | 98 | 113 | 103 | 1000 | 950 | 240 | 240 | ||||

| 5 | 14 | 120 | 121 | 133 | 134 | 900 | 900 | 280 | 280 | ||||

| 6 | 16 | 159 | 162 | 177 | 180 | 900 | 900 | 370 | 370 | ||||

| 7 | 18 | 204 | 211 | 227 | 248 | 900 | 850 | 460 | 460 | ||||

| 8 | 20 | 256 | 236 | 284 | 278 | 900 | 850 | 560 | 560 | ||||

| 9 | 22 | 311 | 284 | 346 | 355 | 900 | 800 | 700 | 700 | ||||

| 10 | 25 | 407 | 362 | 452 | 452 | 900 | 800 | 950 | 950 | ||||

| 11 | 28 | 458 | 443 | 573 | 590 | 800 | 750 | 1220 | 1220 | ||||

| 12 | 30 | 529 | 518 | 661 | 690 | 800 | 750 | 1350 | 1350 | ||||

| 13 | 32 | 604 | 518 | 755 | 740 | 800 | 700 | 1550 | 1550 | ||||

| 14 | 36 | 770 | 673 | 962 | 961 | 800 | 700 | 2040 | 2040 | ||||

| 15 | 40 | 956 | 774 | 1195 | 1190 | 800 | 650 | 2540 | 2540 | ||||

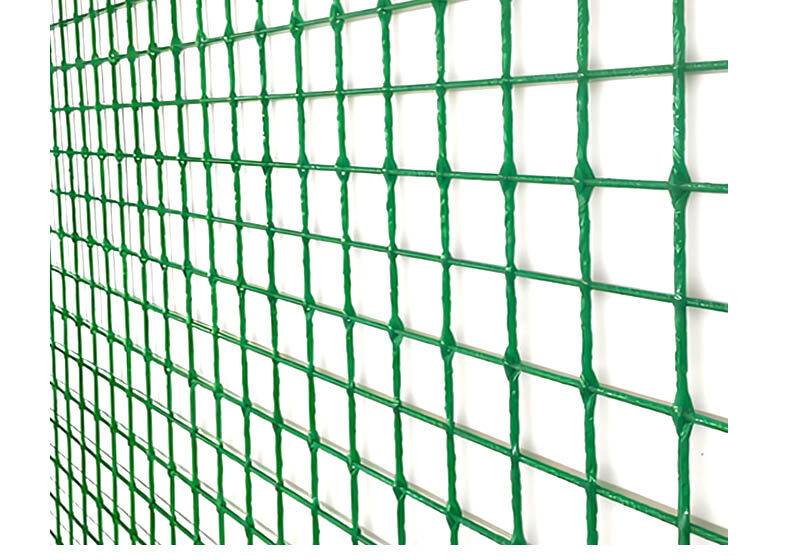

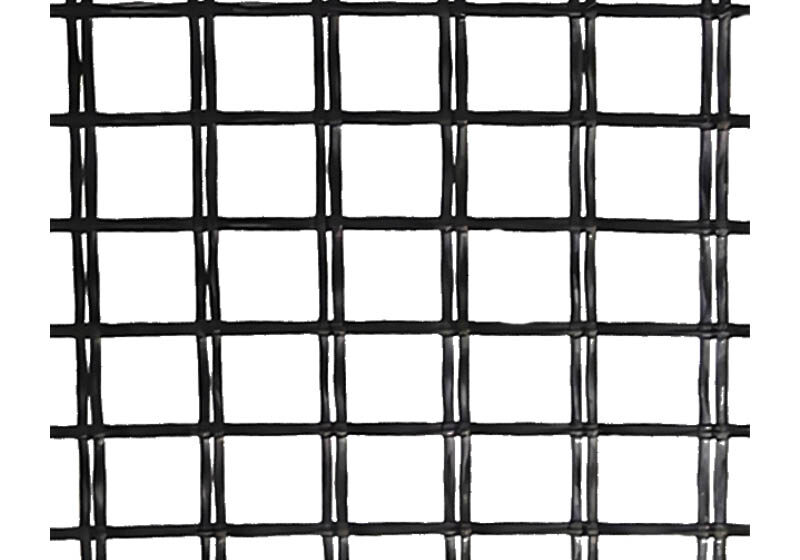

FRP Rebar Mesh, FRP Mesh, GRP Mesh

FRP MESH

What Size We Can Provide Now

| Diameter | Mesh Size | Mesh Size |

| 4mm | 33x33mm | 50x50mm |

| 5mm | 66x66mm | 100x100mm |

| 6mm | 33x66mm | 150x150mm |

| 8mm | 33x99mm | 200x200mm |

| 10mm | / | 50x100mm |

GFRP Fiber Mesh

FRP Rebar Mesh: High-Strength, Corrosion-Resistant

FRP Rebar Mesh is a prefabricated grid made from continuous Fiberglass Reinforced Polymer (GFRP) bars. Designed for superior performance in corrosive environments, it provides a durable, maintenance-free alternative to traditional steel mesh. Its lightweight nature ensures effortless handling and installation, significantly reducing labor time and costs.

Advantage

-

Exceptional Corrosion Resistance: Impervious to rust and chloride attack, significantly extending the service life of concrete structures in harsh environments. Eliminate costly repairs and maintenance.

-

High Strength-to-Weight Ratio: Offers tensile strength greater than steel at just 1/4 the weight. Dramatically reduces transportation costs and simplifies on-site handling and installation.

-

Non-Conductive & Electromagnetically Neutral: Perfect for sensitive applications like MRI suites, power plants, and communication facilities where electrical isolation or radio transparency is critical.

-

Non-Magnetic: Ensures zero magnetic interference, making it the ideal choice for medical imaging centers, scientific laboratories, and military installations.

-

Low Thermal Conductivity: Provides superior insulation compared to steel, improving energy efficiency and reducing thermal bridging in structures.

Application

Our Fiberglass Rebar is the material of choice for engineers and contractors worldwide in these key sectors:

-

Marine & Coastal Structures

Seawalls, docks, piers, jetties, offshore platforms – where saltwater corrosion is a major concern. - Bridges & Highways

Bridge decks, overpasses, and road infrastructure exposed to de-icing salts and heavy traffic. - Wastewater Treatment Plants

Tanks, pipes, and channels exposed to corrosive gases and chemicals. - Tunnels & Underground Structures

Especially in high-moisture or chemically aggressive environments. - Nuclear & Power Facilities

Radiation shielding rooms and non-conductive structural components. - Electromagnetic-Sensitive Buildings

Hospitals (MRI suites), data centers, research labs, and military installations. - Historic Restoration & Lightweight Constructions

Ideal for retrofitting old structures or building lightweight concrete elements.

WHY CHOOSE US

✅ 20+ Years of Experience in the Fiberglass Industry

As a trusted export partner, we bring over two decades of expertise in sourcing and supplying high-quality fiberglass products to global markets. Our deep industry knowledge ensures reliable product standards and smooth international trade operations.

✅ Customization & OEM/ODM Support

We offer full customization services — including size, color, branding, and packaging — to meet your specific market requirements. Flexible OEM and ODM solutions are available for long-term partnerships.

✅ Warranty & Dedicated After-Sales Service

All products come with a manufacturer-backed warranty. In case of any issues, we provide prompt after-sales support, including technical guidance and problem resolution. Our team is always available to assist you post-purchase.

✅ Efficient Shipping & Cost-Effective Packaging

Goods are packed in standard export packaging, and we carefully calculate volume and weight to maximize container space and reduce shipping costs for you — helping improve your bottom line.

✅ Flexible Sample Policy

We offer free samples to help you evaluate product quality before placing bulk orders. Customers are only responsible for the express shipping fee, ensuring a low-risk way to start cooperation.

FAQ

_________________________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________________________

■ FRP Rebar Physical and Mechanical Properties

_________________________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________________________

■ Can FRP Anchor Replace Steel Anchor?

_________________________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________________________

CHINA FRP PRODUCTS MANUFACTURE- GOOYI

Inquiry please contact us now!

We guarantee to provide clients with the high-quality products and competive price. experienced export sales and service team. 100% ensure you will be satisfied with our products.

Email

Whatsapp ✆:+86 15350598856

Web: www.chinaestop.cn

Free sample can be provide, quotation will be provide within 24 hours.