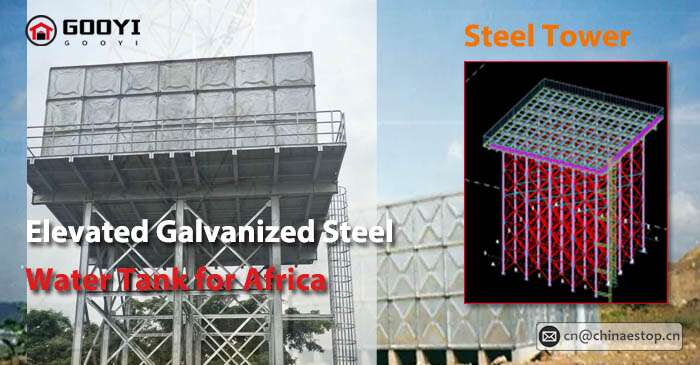

Elevated Galvanized Steel Water Tank for Africa

Elevated hot-dip galvanized water tank is a common water storage equipment, widely used in urban water supply system, fire protection system, industrial water storage and other scenarios. Here are some detailed information about elevated hot-dip galvanized water tank,We manufacturing, supply, and export of Galvanized Steel(HDG) and GRP water tanks to the Africa.

Structure and material

Material: The main material of the elevated hot-dip galvanized water tank is steel plate, which has been hot-dip galvanized. Hot-dip galvanizing refers to immersing steel products in molten zinc liquid so that the zinc layer is firmly attached to the surface of the steel, thereby providing long-term anti-corrosion protection.

Structure: The water tank usually consists of a base, a cylinder, a top cover and a supporting structure. The base and the supporting structure are used to fix and support the entire water tank to ensure its stability. The cylinder is the main water storage part, and the top cover is used to close the water tank and prevent pollutants from entering.

Features

Anti-corrosion performance: The hot-dip galvanizing treatment makes the water tank have excellent anti-corrosion performance, and it can be used in outdoor environments for a long time without rusting.

Weather resistance: The hot-dip galvanizing layer can resist the influence of ultraviolet rays, moisture and other environmental factors, extending the service life of the water tank.

High strength: The use of high-quality steel plates and reasonable structural design makes the water tank have high strength and stability, and can withstand large water pressure and wind loads.

Easy maintenance: The interior of the water tank is smooth, easy to clean and maintain, and reduces the growth of scale and microorganisms.

Safe and reliable: Elevated water tanks are usually equipped with accessories such as safety valves, pressure gauges, and liquid level gauges to ensure the safe operation of the water tank.

Application

Urban water supply: High-level water towers used in urban water supply systems to ensure the stability and reliability of water supply systems.

Fire reserve: As a backup water source for fire protection systems, it ensures that there is sufficient water supply when a fire occurs.

Industrial water: Used for cooling water and process water storage in industrial facilities such as factories and power plants.

Rural water supply: In remote areas or rural areas, it is used for centralized water supply and storage.

Building water supply: In the secondary water supply system of high-rise buildings, it is used to store and adjust water pressure.

Design and installation

Design: According to actual needs and site conditions, the design of parameters such as water tank capacity, height, and diameter is carried out. Usually, factors such as the maximum water level, minimum water level, and location of the inlet and outlet pipes of the water tank need to be considered.

Infrastructure: The foundation of the water tank needs to be solid and flat, able to withstand the weight and water pressure of the water tank. The foundation is usually cast in concrete.

Installation: When installing the water tank, you need to pay attention to the horizontality and verticality to ensure the stability and safety of the water tank. During the installation process, you also need to connect the inlet and outlet pipes, drain pipes, overflow pipes and other accessories.

Maintenance

Regular inspection: Regularly check the appearance and structure of the water tank to ensure that there is no damage or corrosion.

Cleaning: Regularly clean the inside of the water tank to prevent water pollution and scale accumulation.

Accessory inspection: Check the working status of accessories such as safety valves, pressure gauges, and liquid level gauges to ensure their normal operation.

Anti-corrosion treatment: For locally corroded or damaged parts, repair and re-galvanize in time.

Elevated hot-dip galvanized water tanks have become the preferred equipment for many water supply and storage systems due to their excellent performance and wide range of applications.

Manufacture Standard

BS1654 (BS 1564 Prestressed Rectangular Tanks) provide the best earthquake resistance and durability in Steel Sectional Water Storage Tanks. This British Standard specifies requirement for pressed steel sectional rectangular tanks, working under a pressure not greater than the static head corresponding to the depth of the tanks, built up of pressed steel plates 1220mm square used to contain cold water, hot water, potable liquids, certain oils and chemicals.

Keywords :

Hot Dipped Galvanized Sectional Water Tanks

Elevated Water Tank

Galvanized Water Tank for Africa

Overhead Water Tank

Inquiry please contact:

Email : cn@chinaestop.cn

Whatsapp✆:+86 15350598856

Web: www.chinaestop.cn

————————————————————————————————————————

“ Wish to be your best partner in China! Welcome to visit our company”