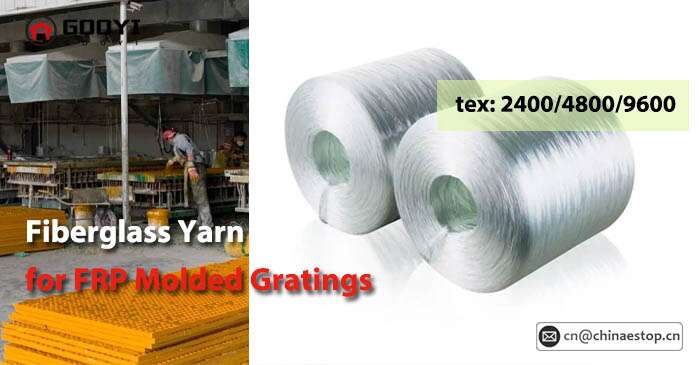

Fiberglass yarn classified according to different yarn diameters

Fiberglass yarn classified according to different yarn diameters Glass fiber yarn can be divided into several categories according to the diameter of the single filament. These categories help meet the needs of different application scenarios. Glass fiber single filaments are cylindrical, and the thickness can be expressed by diameter. The classification based on the single filament … Read more